solution

001 “We plan to install our first molding machine. How shall we start?”

Matsuda Seisakusho’s professionals will be happy to discuss this with you and thoroughly satisfy your needs.

Step 1 Inquiry

Please inquire by filling in the inquiry form or calling us.

Step 2 Discussion

Our professionals will discuss with you to thoroughly understand your needs concerning not only specifications for the machine and auxiliary equipment and the installation environment, but also specification for molds and materials.

If needed, we will conduct a test using our demonstration machine and work out details for adoption.

Step 3 Order placement and start of manufacturing

After order placement, we will draw a detailed design of the equipment, make arrangement for parts, and do an assembled trial run. After completion, please come to our factory and observe the completion.

Step 4 Product delivery

A company specialized in shipment and installation of heavy goods will install the molding machine at your factory. Matsuda’s workers will then make trial operation and adjustment to complete the work.

Our specialized service department will be engaged in any troubles after the delivery.

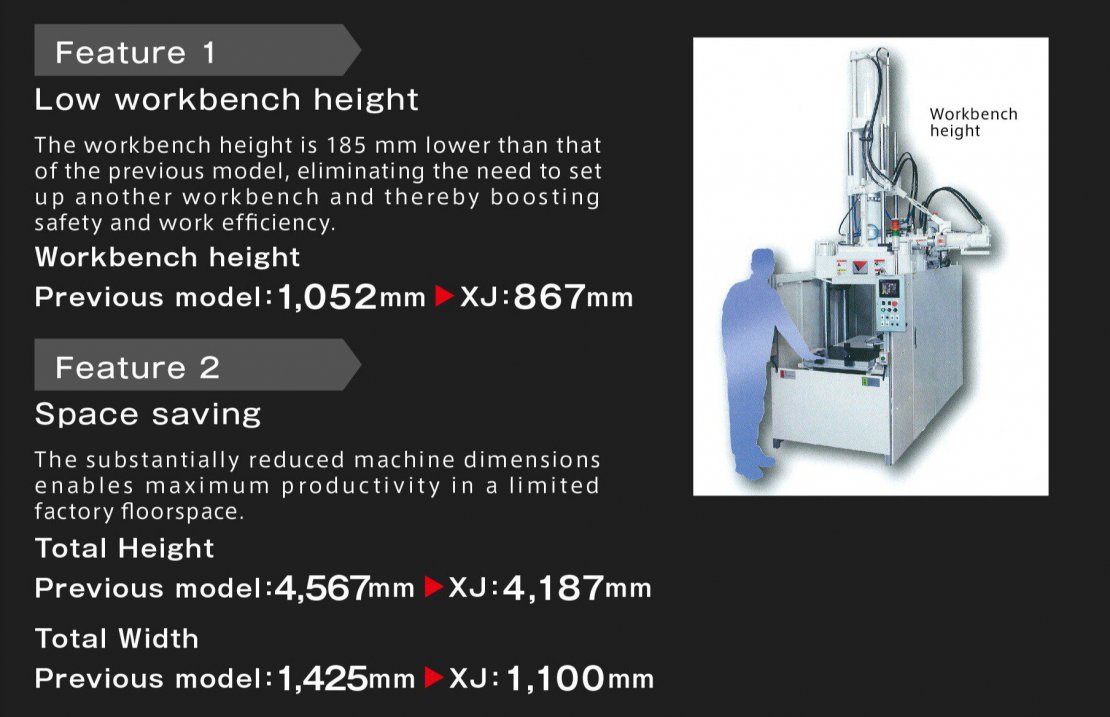

002 “Our factory space is tight but we want to raise production capacity.”

Matsuda Seisakusho has a variety of space-saving models and is capable of customizing a model according to your request.

We have a variety of space-saving models, including the main XJ Series and a 50-ton class small injection molding machine.

We can also accommodate to your request to customize the machine in various ways, including changes in a control panel or the direction of a screw.

Matsuda’s model that enables to reduce the installation space

・Matsuda’s original XJ Series has achieved about a 75% reduction in installment space compared to the previous model (by Matsuda’s comparison).

Matsuda’s models that enable to reduce a molding cycle time

・The moving parts of the XJ Series function more smoothly than the previous model.

・The VS3 Series has reduced space inside its vacuum evacuated chamber and efficiently shortened the molding cycle time.

Matsuda’s models that help increase operating rates

・Addition of some options to a standard model helps significantly shorten the time to change molds.

・The trouble analysis support function can be installed in order to quickly detect causes of equipment troubles.

003 “How can we make a production line in response to the labor shortage?”

Matsuda Seisakusho has a variety of automated equipment, that satisfies your needs.

We have a variety of automated equipment that satisfies your needs, from simple take-out robots to the equipment to debur, clean molds, disassemble molds, or inspect a defect of molded products.

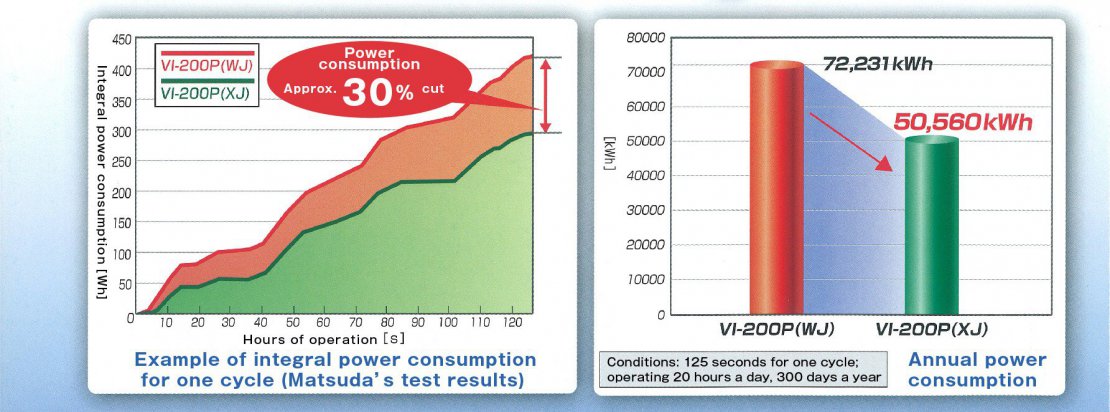

004 “How much can we benefit by introducing an energy-efficient molding machine?”

The new model, that is equipped with a high-performance insulation plate and has other improvements, can reduce power consumption by about 30% compared to the previous model.

Introduced the energy-efficient rotation controled pump and the sophisticated heat insulation plate, the latest model enables you to reduce approximately 30% comsumption compared to the previous model (Our test results).

In addition, the old models can be improved by adding optional functions. We can also help meet requirements for certification for governmental subsidies or tax-reduction measures.

005 “Will you give us a demonstration using our existing molds?”

Matsuda Seisakusho is ready and able to perform a demonstration, using your own mold and materials.

We can conduct a demonstration of many of our models, including our main XJ Series machine, vacuum injection molding machine, and vent-type injection unit, by using your mold and materials, at any time. We also have many molds for demonstration, which can be used in case you do not have your own mold.

006 “How can we disassemble a complex mold?”

We have experienced mold disassemblers for various mold structures, such as multi-facets, reversed, the cores on both sides.

We have manufactured disassemblers for diverse mold structures, for disassembly of multi facets, to reverse a mold, or to remove the cores on both sides.

007 “Are we better off by replacing our aging machine with a new model? ”

Matsuda Seisakusho believes the best results are obtained from use of the latest model but can also add additional functions to your old model.

We recommend you to purchase the latest model in order to have significantly improved functions and performance. You can expect less downtime, stable and higher rate of operation with the latest model.

However, if you prefer, we will also modify your old model by overhauling it or by adding optional functions.

008 “How good is a supporting system of you after installation? Is an overseas support available for you?”

Matsuda Seisakusho(Our) team visit your factory in Japan and abroad for supporting you.

Our team supports customers(you) all over Japan from 3 service centers, also in China and Thailand service centers support you in East Asia and Southeast Asia.

We also have agencies in North America and our service staff will travel from Japan to your country as needed.

009 “We want to reduce molding defects.”

Matsuda Seisakusho’s proprietary technologies used in machines such as our vacuum injection molding machines and vent-type injection units contributed to significant reduction in molding defects.

We have significantly reduced molding defects with our proprietary technologies used in our vacuum injection molding machines and vent-type injection units. We have also accumulated abundant know-how on measures to prevent defects from injection molding machines for rubber. We welcome your inquiries.

- 001“We plan to install our first molding machine. How shall we start?”

- 002“Our factory space is tight but we want to raise production capacity.”

- 003“How can we make a production line in response to the labor shortage?”

- 004“How much can we benefit by introducing an energy-efficient molding machine?”

- 005“Will you give us a demonstration using our existing molds?”

- 006“How can we disassemble a complex mold?”

- 007“Are we better off by replacing our aging machine with a new model? ”

- 008“How good is a supporting system of you after installation? Is an overseas support available for you?”

- 009“We want to reduce molding defects.”