Product Information

Other molding machines

Matsuda Seisakusho can provide machines that best satisfy your needs from its rich product lineup, including large-sized or small-sized injection molding machines, vacuum presses, compression molding machines, and transfer molding machines.

Custom-made for better production

Matsuda responds to all kinds of customers’ requests –such as for higher clamping force, greater injection capacity, and special mold structure, which are not listed in catalogue models, and stricter internal safety standards, which ordinarily cannot be met by overseas makers.

History, starting with compression molding machines

Since development of Japan’s first hydraulic molding machine in 1927, Matsuda has continued its advance in developing compression molding machines, transfer molding machines, and injection molding machines.

Based on its accumulated know-how, Matsuda provides diverse molding machines to customers.

Dealing with automated systems

Matsuda also takes an active approach to labor saving, including use of simplified takeout devices that use orthogonal cylinders and fully-automated molding systems that use a multi-joint robot.

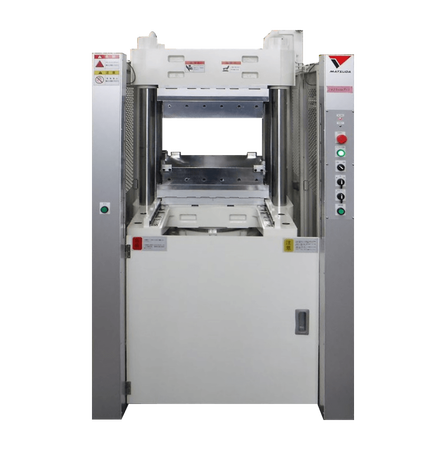

Vacuum press machine

SPSeries

Substantial drop in defects caused by air.

Can be used to disassemble complex molds.

Matsuda has manufactured numerous types, including side plate, vacuum pot, and multiple types.

Machine specifications

Example:SP-201

| Clamping force | 1,960kN (200ton) |

|---|---|

| Daylight | 350 mm |

| Open/close stroke | 350 mm |

| Heating platen diameter | 500×500 mm |

| First-stage ejector stroke | 400 mm |

| First-stage ejector reverse | 75 ° |

| Second-stage ejector stroke | 280 mm |

| Hydraulic system | Rotation control pump |

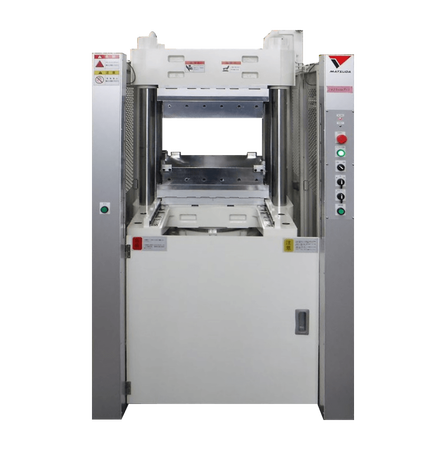

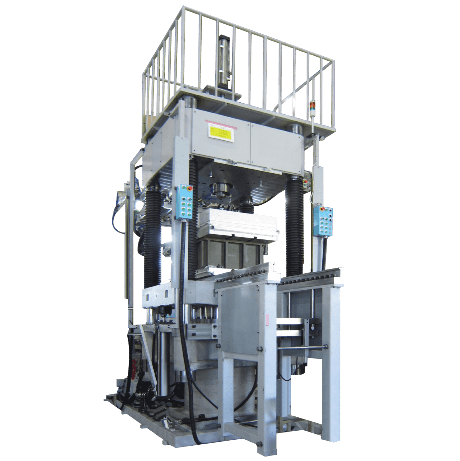

Compression molding machine

BCSeries

High-precision, reliable, standard molding machine.

High precision, high durability and easy to use.

Matsuda has numerous product types, from 15 tons to 3,000 tons.

Machine specifications

Example:BC-150

| Clamping force | 1,470kN (150ton) |

|---|---|

| Daylight | 550 mm |

| Open/close stroke | 375 mm |

| Heating platen diameter | 580×580 mm |

| Ejector protrusion | 100 mm |

| Ejector stroke | 200 mm |

| Hydraulic system | Rotation control pump |

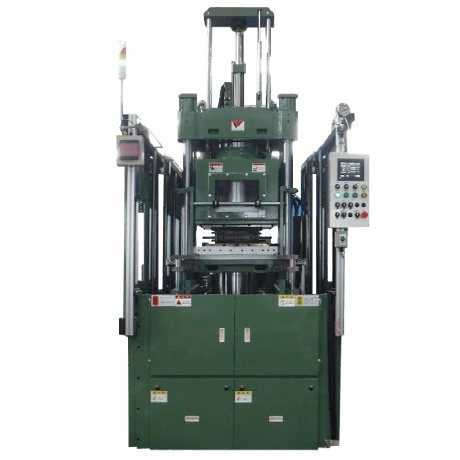

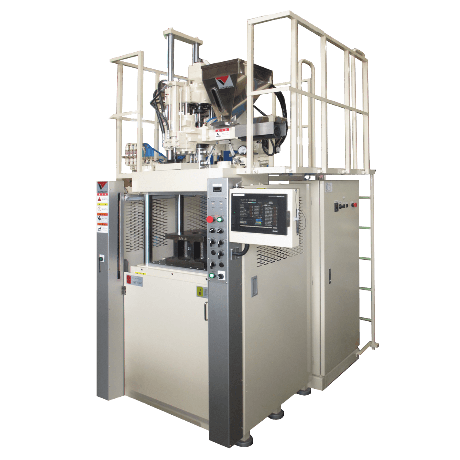

Transfer molding machine

TSeries

Suitable for low-pressure sealing molding and excellent in cost performance.

Lower orientation in filler than injection molding, enabling injection at low pressure.

Machine specifications

Example:T-75

| Clamping force | 735kN (75ton) |

|---|---|

| Daylight | 700 mm |

| Open/close stroke | 350 mm |

| Heating platen diameter | 500×400 mm |

| Ejector protrusion | 100 mm |

| Ejector stroke | 200 mm |

| Hydraulic system | Rotation control pump |

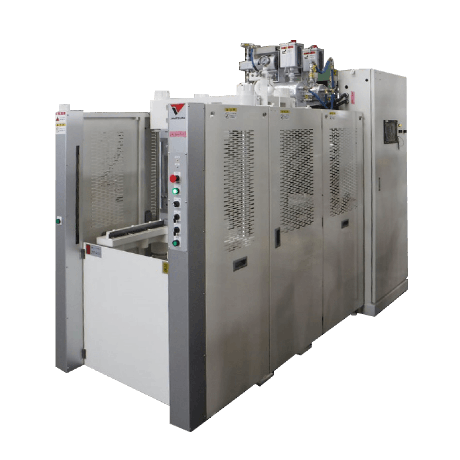

Large-sized injection molding machine

VI-PSeries

Large-capacity injection equipment

High precision, and high durability.

Japan’s top-class injection capacity of 30,000cm3at maximum

Matsuda’s injection equipment is excellent in terms of ease of maintenance.

Machine specifications

Example:VI-500P-75/140SPS

| Clamping force | 4,900kN (500ton) |

|---|---|

| Daylight | 850 mm |

| Open/close stroke | 500 mm |

| Heating platen diameter | 1,200×800 mm |

| Injection capacity | 12,000 cm3 |

| Injection pressure | 180 MPa |

| Hydraulic system | Variable piston pump |

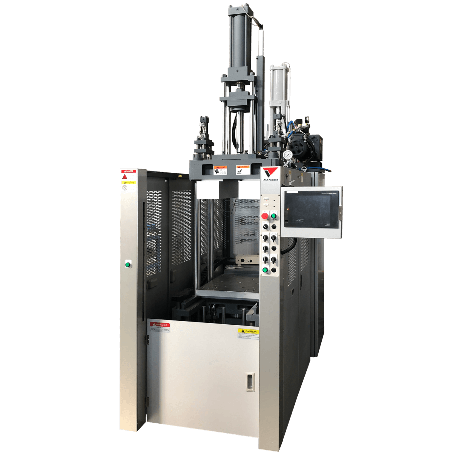

Small-sized Injection Molding Machine

VI-PSeries

Suitable for ultra-compact, ultra-precision molding.

Can be used for molding of 10-50 tons and 31cm3 at minimum.

This machine is available for fully-automated single-cavity molding.

Machine specifications

Example:VI-50P-20GS

| Clamping force | 502kN (50ton) |

|---|---|

| Daylight | 275 mm |

| Open/close stroke | 200 mm |

| Heating platen diameter | 300×300 mm |

| Injection capacity | 31 cm3 |

| Injection pressure | 213 MPa |

| Hydraulic system | Variable piston pump |

| Machine dimensions | W550×D1,638 mm |

| ×H2,785 mm |