Product Information

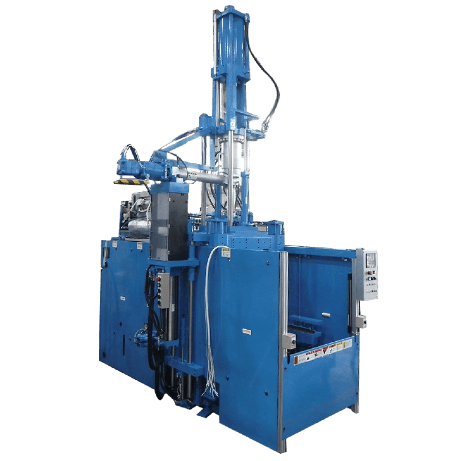

Injection molding machines

Matsuda Seisakusho has a rich line-up in its mainstay products, injection molding machines, including vertical or horizontal types and a variety of clamping force and injection capacity combinations. Let us make a proposal on the best injection molding machine for your factory.

High precision and high quality

Based on its proven know-how accumulated through more than 70 years of development work and production of over 10,000 units, Matsuda Seisakusho delivers highly-reliable molding machines which incorporate the latest CAE-analysis-based technology.

A rich product line-up

Vertical types

Clamping force:20~1500 ton

Injection capacity:30~30,000 cm3

Horizontal type

Clamping force:35~350 ton

Injection capacity:49~1310cm3

Machines for various thermosetting plastics

Matsuda’s injection molding machines can handle diverse materials, including general-purpose rubber, special rubber (such as silicone rubber and fluoro rubber), and thermosetting plastics (such as phenol, epoxy and unsaturated rubber).

We have vast expertise in handling thermosetting materials.

Machine specifications

Example:VI-200P(XJ)-40/70SPR2

| Clamping force | 1,960kN (200ton) |

|---|---|

| Daylight | 600 mm |

| Open/close stroke | 400 mm |

| Heating platen diameter | 600×600 mm |

| Ejector protrusion | 100 mm |

| Ejector stroke | 200 mm |

| Injection capacity | 1,500 cm3 |

| Injection pressure | 188 MPa |

| Work height | 867 mm |

| Hydraulic system | Rotation control pump |

Machine specifications

Example:VI-200V(S3)-40/70SPR2

| Clamping force | 1,960kN (200ton) |

|---|---|

| Daylight | 600 mm |

| Open/close stroke | 400 mm |

| Minimum mold pressure | 225 mm |

| Maximum mold pressure | 475 mm |

| Heating platen diameter | 650×650 mm |

| Ejector protrusion | 100 mm |

| Ejector stroke | 200 mm |

| Injection capacity | 1,500 cm3 |

| Injection pressure | 188 MPa |

| Work height | 897 mm |

| Hydraulic system | Rotation control pump |

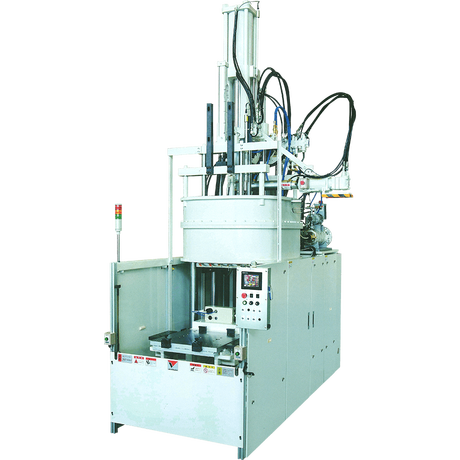

Vertical-type injection molding machine for rubber and for thermosetting plastics

SJSeries

A standard model of a rich line-up of clamping force choices.

Clamping force:75~400ton Injection capacity:500~4,000cm3

The long-selling model that satisfies many customers’ needs.

Machine specifications

Example:VI-75P(SJ)-40/60SPR5(500)

| Clamping force | 735kN (75ton) |

|---|---|

| Daylight | 500 mm |

| Open/close stroke | 350 mm |

| Heating platen diameter | 500×400 mm |

| Ejector protrusion | 100 mm |

| Ejector stroke | 200 mm |

| Injection capacity | 500 cm3 |

| Injection pressure | 188 MPa |

| Hydraulic system | Variable piston pump |

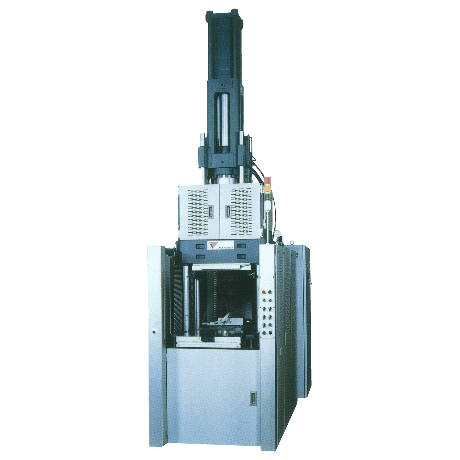

Vertical-type vacuum injection molding machine for rubber

VS2Series

Accepts all types of molds.

Feature: Substantial reduction in defects caused by air traps in molded products.

The entire mold can be inside the vacuum chamber, preventing trapped air even if the mold has a complicated structure.

Machine specifications

Example:VI-200V(S2)-50/70SPR3

| Clamping force | 1,960kN (200ton) |

|---|---|

| Daylight | 800 mm |

| Open/close stroke | 500 mm |

| Heating platen diameter | 650×650 mm |

| Ejector protrusion | 100 mm |

| Ejector stroke | 200 mm |

| Injection capacity | 3,000 cm3 |

| Injection pressure | 180 MPa |

| Hydraulic system | Variable piston pump |

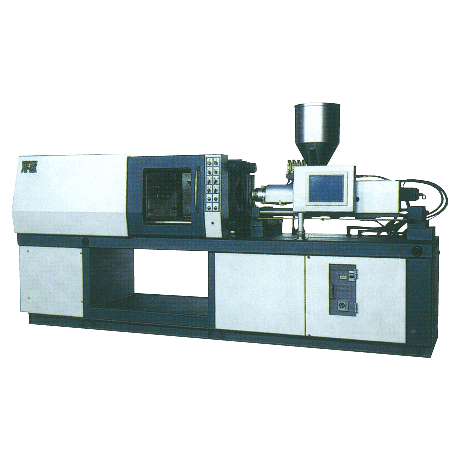

Horizontal-type injection molding machine for rubber and for thermosetting plastics

FSeries

A simplified, easy-to-use long-selling model of a horizontal-type injection molding machine.

This direct-pressure-type mold clamping device, that is most appropriate for thermosetting plastics and rubber, enables stable molding.

Machine specifications

Example:75F-36K

| Clamping force | 735kN (75ton) |

|---|---|

| Daylight | 600 mm |

| Open/close stroke | 400 mm |

| Die plate dimensions | 560×560 mm |

| Diver spacing | 395×395 mm |

| Ejector protrusion | 99 mm |

| Injection capacity | 180 cm3 |

| Injection pressure | 165 MPa |

| Hydraulic system | Variable piston pump |

Injection molding machine for silicone rubber

Millablesilicone rubber typeLiquidsilicone rubber type

Suitable for satisfying all kinds of needs, from millable silicone rubber to liquid silicone rubber.

Matsuda Seisakusho’s know-how is used in adopting the push feeder for millable silicone rubber materials and the dynamic mixer for LIM molding for this model.

Machine specifications

Example:VI-200P(XJ)-40/60SPR6-P

| Clamping force | 1,960kN (200ton) |

|---|---|

| Daylight | 600 mm |

| Open/close stroke | 400 mm |

| Heating platen diameter | 600×600 mm |

| Ejector protrusion | 100 mm |

| Ejector stroke | 200 mm |

| Injection capacity | 1,100 cm3 |

| Injection pressure | 188 MPa |

| Push feeder capacity | 9 L |

| Work height | 867 mm |

| Hydraulic system | Rotation control pump |

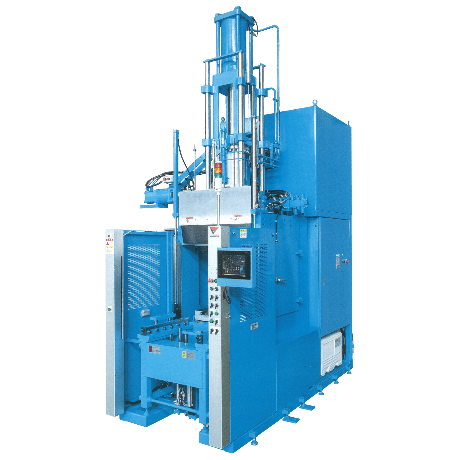

Injection molding machine for BMC

DLSeries

Enable the production capacity to be doubled by using doubled clamping machine.

Different molds can be set on the left and right sides.

This structure is appropriate for molded products that require an inserting operation.

Machine specifications

Example:YMLD100-50/90FLN

| Clamping force | 989kN (100ton) |

|---|---|

| Daylight | 700 mm |

| Open/close stroke | 350 mm |

| Mold mounting plate dimensions | 620×580 mm |

| Ejector protrusion | 80 mm |

| Injection capacity | 1,500 cm3 |

| Injection pressure | 58 MPa |

| Push feeder capacity | 35 L |

| Hydraulic system | Variable piston pump |